A considerable challenge for researchers that investigate human disease is to be able to accurately recreate the disease outside of the human body. Disease investigation in vitro, (or ‘in a dish’) is described as ‘disease modelling’ and generally involves isolating or generating diseased cells before subjecting them to various conditions. Disease models are an invaluable investigative and therapeutic tool; enabling screening of drugs and further investigation into the cause of disease symptoms. However, many in vitro disease models cannot fully recreate the complexities of a disease environment, such as specific cellular interactions and tissue organisation. It is for this reason that animal disease models are so popular within the research community, as they can provide a more accurate representation of the investigated disease.

However, newer technologies may enable in vitro disease reconstruction that eliminate the limitations of previous cell-based and animal models. Engineering approaches, such as 3D printing, are being increasingly incorporated into biological research. 3D printing is a highly versatile tool that has been seen to have many applications in a variety of disciplines and works by building up a 3D construct layer by layer. I caught up with 2nd year PhD student Geoff Potjewyd, who has recently published a review in Trends in Biotechnology that covers the use of 3D bioprinting in vascular dementia tissue modelling.

Can you briefly describe your project?

I create 3D cell models of the brain’s neurovascular unit to investigate neurovascular dysfunction in Alzheimer’s disease. To do this I use patient stem cells, 3D-bioprinting and specialised biomaterials to recreate the complex 3D and multicellular environment of the neurovascular unit within the controlled setting of the lab. This allows me to dissect specific cellular and molecular mechanisms that affect the cells of the brain and lead to Alzheimer’s disease through a physiologically relevant and human model. The patient stem cells also allow for the study of how specific Alzheimer’s disease mutations in different cells can affect the neurovascular unit.

Can you briefly describe 3D bioprinting?

3D bioprinting is the computer automated deposition of biological matter into a defined structure. This uses a process called additive manufacturing, where a 3D structure is built layer by layer. There are many different 3D-printing based approaches which can be used to make a scaffold for cells, but the technique that we use is called micro-extrusion bioprinting, as it has minimal negative effects on cells compared to some other 3D-printing techniques.

What is the advantage of 3D bioprinting in your area?

Bioprinting provides advantages in both of my scientific disciplines: as a cell biologist, bioprinting allows for the development of bespoke 3D-cell models to answer precise biological questions; and from a tissue engineering perspective, bioprinting enables the development of complex models that allow for cell-cell crosstalk at a biochemical and biophysical level. These are both the advantages over manual casting (non-bioprinting) which relies on self-assembly of cells, although this can still be useful in certain applications!

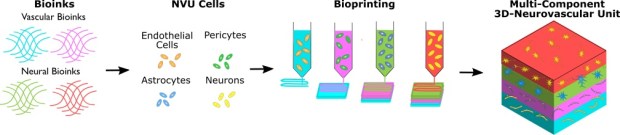

Construction of 3D multicomponent neurovascular unit – Different NVU cell types can be combined with specialised biomaterials, known as bioinks, and bioprinted to manufacture multicomponent 3D NVU models. Neural and vascular cells are encapsulated within bioinks suitable for their viability and growth. Bioprinting allows for precise positioning of the neural and vascular cells to form appropriate interactive interfaces that mimic the in vivo situation.

What are some other applications of 3D bioprinting?

While I am using bioprinting to model disease, the technique can also be used to create tissues and organs for direct implantation into the body; a common application for this research the creation osteochondral implants but can be applied to soft tissues like the brain. More widely, 3D-printing in medicine has been used commonly to create prosthetics that are bespoke to patient needs, but has also been used to print poly-pharmaceutics – drugs that contain multiple pharmaceutical compounds for controlled release of multiple drugs in one pill.

Check out Geoff’s review DOI – 10.1016/j.tibtech.2018.01.003

Geoff’s twitter here.

Discover more from Research Hive

Subscribe to get the latest posts sent to your email.

thanks for the credible and interesting information.

LikeLike